Update regarding MgO boards

MOBBTA is in receipt of statements from NHBC and LABC/Premier guarantee announced in the past 14 days.

MOBBTA were both shocked and surprised to learn of this latest change to policy regarding MgO boards.

MOBBTA and its members are not aware of any failures or significant performance issues that have triggered these actions.

Given the reliance on MgO boards to various sectors of industry along with the situation that the world currently finds itself we feel that deadlines stated are completely unworkable. It allows very little consideration to stockists, contractors and building owners that are involved with the supply chain of certain MgO boards to new and ongoing construction projects.

MOBBTA is gravely concerned that fear and knee-jerk reaction is being allowed to prevail over scientific logic, evidence and tried and tested UK certification bodies and that the consequence will be to halt development and deployment of MMC building systems that offer substantial advantages in performance, cost, speed of construction and environmental benefits.

MOBBTA places its trust in UKAS approved test bodies that are then assessed by leading recognised Agrément certification bodies.

All MOBBTA members either carry or are working towards third party accreditation (also known as agrement certificates) provided by BBA or Kiwa BDA. These agrements require that approved products carry an extensive list of onerous durability tests plus frequent audit of factory & quality control measures undertaken by the certificate owner.

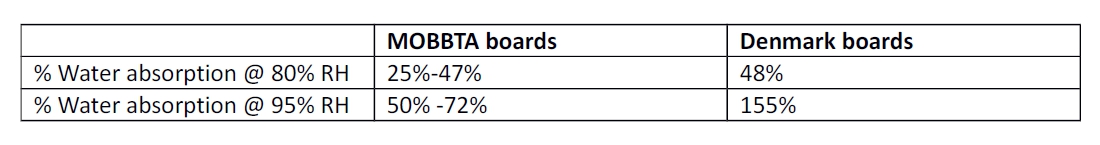

MOBBTA members have collectively supplied in excess of 12,000,000m2 of MgO boards into the UK market in semi-exposed/exterior conditions (defined as service class 2 & 3 conditions according to Eurocode 5 – design for timber structures).

MOBBTA remain committed in working towards the creation of an industry standard in addition to its own standards and wish to involve the NHBC and LABC among leading construction insurance companies as part of the process. In previous meeting between MOBBTA and key industry stakeholders both insurers had stated that they wished to be part of this body of work.

8th April 2020